With an intricate supply chain system, the food sector is one of the most complex industries in the world. That burger you enjoy may have ketchup from Belgium and gherkins from Turkey, for all you know. Such is the interconnectedness of ‘farm’ to ‘fork’ in the borderless world that we live in. And Internet of Things (IoT), especially IoT-enabled transportation management software, has come to play an essential role in it.

IoT has proven to bring profits for supply chain management systems. Besides financial gains, IoT can also bring visibility, transparency, adaption, flexibility, and virtualization across the supply chains. And each of these aspects becomes crucial to the sector, given consumers’ demand for ethical and fair-trade food as also the need for food safety. IoT can help the industry enhance output and productivity at the agricultural, storage, and delivery stages. These services can be performed through operations including-

- Supply chain management

- Greenhouse monitoring

- Social media for open innovation and sentiment analysis

- Intelligent farm machines and drone-based crop imaging

- Food quality assessment using spectral methods and sensor fusion

- Food safety monitoring, using of gene sequencing and Blockchain-based digital traceability

According to research by By 2025, the market for the food industry is expected to be growing at a CAGR of 7%.

Let’s look at the application of IoT across the three significant stages of the farm to fork supply chain:

At the agricultural end

IoT has broadened the possibilities of achieving maximum production and has helped the industry stay environment friendly. IoT tools like cloud computing and sensors have made managing water and soil, water distribution, and accessing meteorological information easier. Technology requirements in the agricultural industry are also growing due to the increased awareness about product origin and process stability among consumers. Proper storage and distribution of the produce are also important factors that have led to increased use of IoT at the agricultural level.

Some examples of innovative use of IoT in agriculture

- Continuous monitoring of quantity and quality of the grain in silos

- Controlling irrigation and use of fertilizers for traditional and hydroponic agriculture

- Use of RFID sensors and egg detectors to analyze the behavior and plan remedies for the welfare of hens in poultry farms

- Use of multispectral images to analyze and control crop quality

- Use of neural networks, support vector machines, and electronic smell techniques to rapidly detect moldy apples in cold stores

- Use of an insect surveillance system in open fields using vibro-acoustic sensors

At the resource management end, IoT can create a ‘smart’ farming environment. Using tools such as cloud computing, big data, multiple-communication-protocol management, artificial intelligence and distributed ledger technologies like Blockchain, the resources can be better utilized and produce increased. These tools can also improve the traceability and productivity of the manufacturing and packaging processes.

With the help of these tools, IoT can perform functions such as comprehensive analysis, predictions and recommendations. IoT can also execute task automation, considering historical and real-time information about crops, machinery, livestock, or humans. All these allow farmers and supply chain managers to foresee factors such as production levels, storage requirements, distribution, and supply chain plans. Such data enables supply chain heads to plan their strategies in advance.

At the storage end

IoT systems can be used to reduce wastage of food products at the storage and transportation ends. This also ensures improved food safety by the utilization of tools such as real-time temperature tracking sensors. The sensors can also be used to manage temperatures in the storage facility. They can also be used to monitor other food safety parameters such as moisture, humidity, pH and odor.

IoT devices allow supply chain heads to trace and monitor goods from the production end right up to last-mile delivery. This helps the brands to gather granular and real-time data. This data can be used to improve both systems and processes, such as optimizing production and distribution schedules. By enabling supply chain heads to monitor food safety data points, the IoT systems assure active cold chain management. IoT for food supply chain management has helped organizations gain higher profits and improved customer satisfaction. It has also assisted supply chain heads to save energy through efficient energy spending.

Warehouse management systems allow supply chain heads to manage warehouses, silos and other storage spaces efficiently. On-premises and cloud deployment of IoT applications allows integration of quality, production, and track-and-trace processes. This ensures direct control of warehouse automation equipment and managing high-volume warehouse operations. By integrating complex supply chain management with warehouse and distribution processes, IoT-based technology allows for the efficient handling of inventories remotely and in real-time. For example, Unmanned Aerial Vehicles (UAVs) are used to maintain stocks and perform traceability tasks in storage facilities. For this purpose, some UAV-based systems make use of a scanner installed on the vehicle. The vehicle performs a pre-defined flight and the scanner reads the barcodes.

The warehouse management system comes with the below-mentioned features to ensure safe storage and reduced wastage:

- Advanced shipment notification

- Maintenance, replenishment, slotting, and rearrangement of inventory

- Transportation wave management

- Packing control and process monitoring

At the delivery end

Another supply chain component where food products need extra care is the delivery and transportation process. With the help of an IoT-powered transportation logistics tool, this critical process can be streamlined in real-time and monitored remotely. For example, IoT-based applications such as QR codes and radio-frequency identification (RFID) tags can monitor goods’ movement. Other technologies such as Blockchain let supply chain heads trace a good throughout the entire cycle. These applications provide minute-by-minute visibility into transportation and ensure safe and cost-effective shipment of the product.

Further, Blockchain’s distributed ledger is almost impossible to alter, making it a perfect tool for maintaining a detailed record of the exchange of ownership that occurs throughout supply chains. Thus, IoT allows users to control and monitor risks cost-effectively and launch remedial measures to strengthen the supply chain process and prevent security breaches.

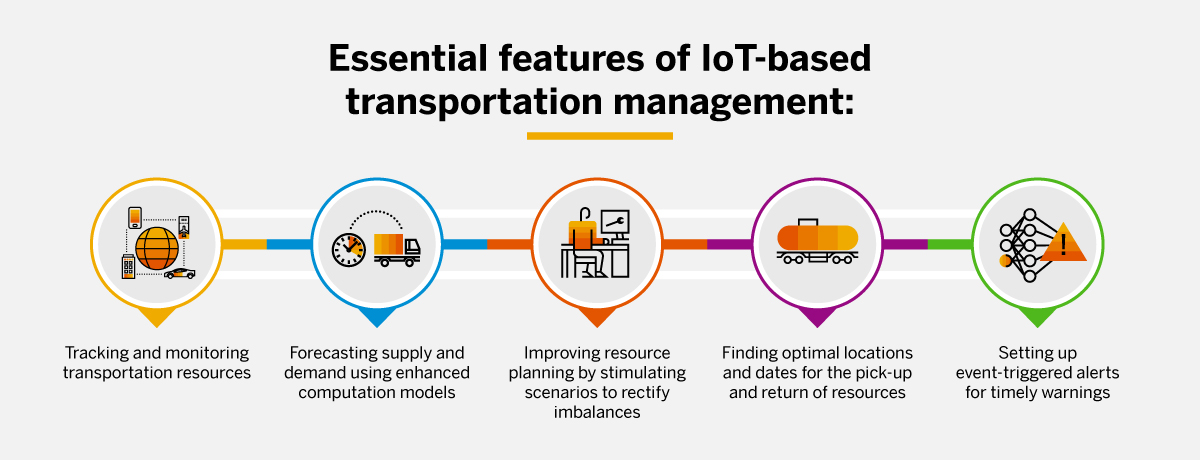

Some other essential features of IoT-based transportation management software are

- Tracking and monitoring transportation resources

- Forecasting supply and demand using enhanced computation models

- Improving transportation resource planning by stimulating scenarios to rectify and prevent imbalances

- Enhancing empty resource movement by finding the optimal locations and dates for the pick-up and return of transportation resources

- Setting up event-triggered alerts for timely warnings

- Automated selling

Food chains can use IoT-based transportation logistics tools to make convenient and timely deliveries to customers. Through efficient supply chain systems, stocks can be managed and replenished in time. IoT-based systems are also being used to directly sell the products to consumers, for example, at vending machines.

- E-tags

The use of e-tags can also prove time-saving and convenient for both customers and the service personnel at the stores. These e-tags are low-cost and use an electronic ink (e-Ink) display. These can be used during the transportation and storage of food items, where they help to monitor the stock. In retail food stores, they can help to monitor shelf life of food items to reduce spoilage and to maintain the inventory. E-tags can also be used for pricing in a store, since they are adaptable and can sync with different sensors in the store. For example, by adapting with a temperature sensor, e-tags can help implement a temperature-controlled inventory management and supply chain system.

- RFID tags

Radio Frequency Identification (RFID) tags facilitate a circuit to broadcast information to an end-user user through a secure system network. RFID tags help retail owners to track and monitor consumer preferences, understand market requirements, and reduce wastage of resources. They can also be used to track and trace perishable food items. Another critical function of the RFID technology is that it can identify the direction of tags. This is done through RFID gates, which can determine whether the products are being received or shipped through the gate.

The data generated through RFID technology can then be used to

- Personalize customer interactions

- Optimize product usage

- Plan future inventories

- Design store layout and shelf displays

- Manage category

This data is also valuable for retail owners. Through RFID data, they can get information about the temperature and humidity history of the product they are buying during the storage and transportation process. This empowers stores to choose the best stocks for their businesses. The data also help the customers to make the right choice while buying a food item.

Through real-time data and analysis, IoT-based systems can notify retail food stores when to restock items. It also provides notifications and alerts about faults and errors in the system. This allows to strengthen the supply chain and maintain better coordination between retail stores and supply chain heads, helping reduce losses.

The owners of retail food outlets can also get insights into consumer behavior through data such as time spent at a kiosk and comparisons made between brands. This feature can help design marketing campaigns and assist in analyzing the impact of existing campaigns.

These benefits are being reaped from tools like sensors to gather data and analyze it, for example, for predicting in-store wait times for customers. All this allows greater customer satisfaction and eventually boosts profits.

- Smart vehicles for smart deliveries

The use of smart vehicles for food delivery can significantly reduce costs associated with operation, transportation, and product handling. For example, in times of the pandemic, a major hurdle for food delivery companies has been the restrictions on movement. People staying home because of the restrictions have also been hesitant to order food online, because of apprehensions of getting infected by the delivery personnel. Using IoT and smart vehicles for food delivery can be the solution for this. Smart vehicles such as drones reduce the need for human intervention, which has become necessary in the present-day scenario of the pandemic.

IoT can thus be used for more advanced functions, such as implementing ‘last mile’ solutions like self-driving vehicles and drones for delivery trips between food outlets and consumer homes. For example, Ericsson, Einride, and Telia have come together to produce self-driving trucks with the help of 5G-powered IoT at the facility of a logistics firm in Sweden. Self-driving cars and drones from Ford and Amazon are already being used for making deliveries. A famous pizza chain started delivering pizza to customers in Miami using smart cars a couple of years ago. All these benefits of IoT-based systems are helping to serve customers better by reducing waiting times and delivery periods.

IoT will only get more embedded in the food supply chain as consumers become more conscious about ethical produce and fair price. And there’s every reason to believe this bodes well for every entity across the food value chain.