In a previous story, I explored the advantages of synchronized planning for supply chain resilience in an age of disruption. The basic theme in that blog was one of digitally enabled planning processes that support the insight, collaboration, and supply chain agility needed to synchronize plans across long-term, mid-term, and short-term time horizons. The implied scenario was one in which the organization owns the execution phase – meaning that the company itself does the manufacturing.

Contract manufacturing is different

One relevant question is: What about contract manufacturing? How does synchronized planning apply to companies that outsource their manufacturing?

Take for instance, the high-tech industry. Most companies that make computers and other high-tech devices are essentially design and brand owners who work with oversees partners to build the products they sell. For these companies, their relationship to execution is different. They don’t necessarily require the linkages that connect the boardroom to the shop floor within their own enterprise.

Nevertheless, they cannot afford to abandon oversight with their trading partners. If they want their brand to thrive, they need ways to monitor manufacturing progress, ensure quality, and coordinate activities around logistics.

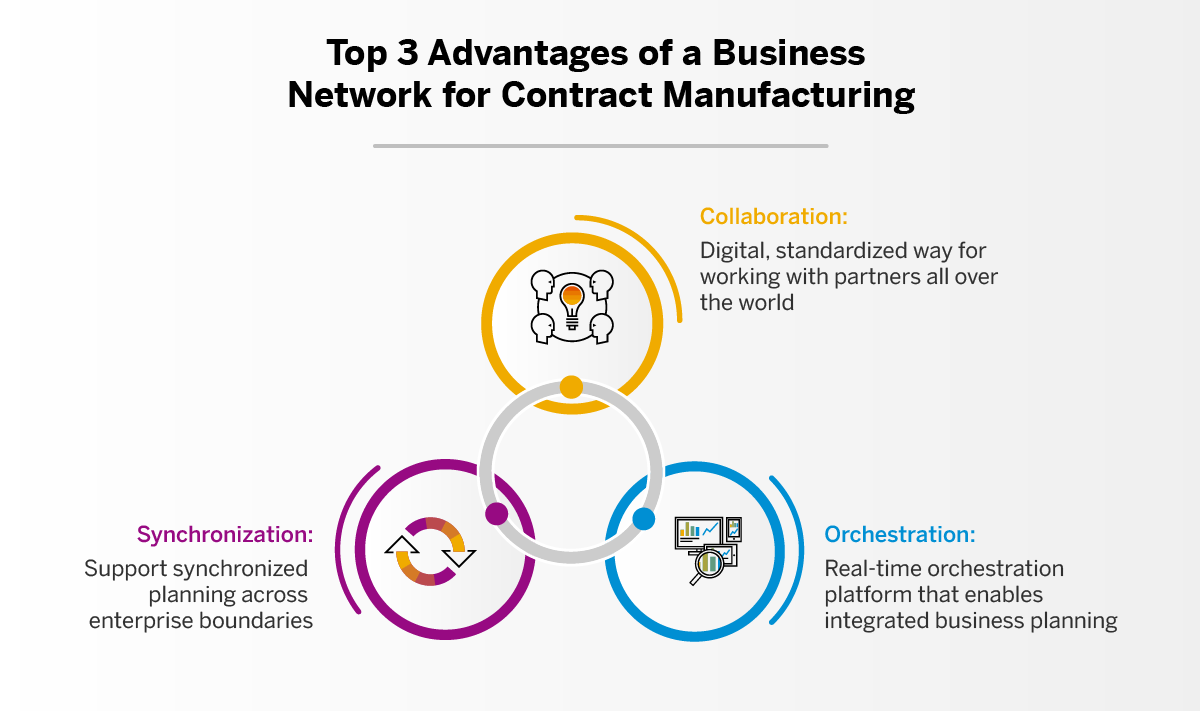

Collaborating with your business network

This is where the importance of business networks comes into play. Today’s globally dispersed supply chains require digital, standardized ways for connecting to and working with partners all over the world.

Business networks that connect trading partners in a many-to-many way offer this at much higher scalability and efficiency. And because the global economy is increasingly subject to shocks such as COVID, Brexit, or natural disasters, these business networks need to be flexible enough to support new plans as they’re modified, onboard new trading partners quickly, and unlock additional content to collaborate on.

Speed and efficiency are of the essence. Think of business networks like the “content aware” internet of business relationships. Organizations want to connect once and then share business data in real time with any trading partner they are dealing with, potentially over multiple tiers. For a brand owner connecting with a contract manufacturer and their suppliers, this means dozens of data objects that need to be exposed and shared.

In this context, outdated peer-to-peer data connections like electronic data interchange (EDI), flat files, e-mails, and dedicated portals require too much effort to build and maintain. They’re brittle when it comes to changing business dynamics. For suppliers, such approaches meant that you need to adapt to different brand owners’ proprietary way of connecting. Business networks take that work away. You connect once and are ready to do business with anyone else on the network adopting a common data model (canonical).

Based in the cloud, business networks provide a standardized way to share data and collaborate. Finding and onboarding new suppliers and partners is accelerated. Business networks can also support complex, multi-tier supply chain relationships that may include third party logistics providers and distribution partners.

Take for instance the making of a strategic subcomponent – like a high-end camera in a laptop computer. The brand owner in this case might want to work with a specialized vendor to manufacture the camera to detailed specifications and then dropship it to the primary contract manufacturer, who then adds it to the laptop. Business networks can support such arrangements with visibility for all parties involved.

Orchestration in real-time

We can also think of business networks as real-time orchestration platforms that enable integrated business planning across globally dispersed supply chain partners. Integrated business planning brings together all the functions in the design-to-operate lifecycle. Phases of this lifecycle include design, manufacturing, logistics and operations – with the planning function interfused throughout.

Organizations can use business networks to incorporate demand signals into the plan, make design changes that reflect what customers want, manage the handoff to manufacturing, run the associated logistics, and even track the product during the operations phase – from delivery to the customer to the support and warranty phase. With data sharing, real-time visibility, collaboration tools, and communications, a business network should enable an organization to orchestrate all the activities from design to operate to deliver better experiences to customers.

Synchronization made possible

With improved abilities to orchestrate planning and execution activities throughout the supply chain, organizations can also use business networks to support synchronized planning across enterprise boundaries. Collaboration with partners and access to data and insight makes for better long-term strategic planning and represents a win-win situation between trading partners. Easy onboarding and flexible ways to connect with new partners helps with mid- and long-term plan corrections. And when it comes to execution, real-time visibility and tracking can help ensure that plans go off without a hitch. The result is better agility for responding to change.