In prior articles, I have focused on the importance of synchronized planning for organizations seeking to navigate an economy characterized by disruption. The first article focused on the idea of synchronized planning – the need to approach long, mid, and short-term planning as a continuum so that you can realize strategic goals at the level of execution. The second article examined how synchronized planning can work in the context of contract manufacturing – where a company designs the product in house but outsources the production function.

To wrap up this series, I’d like to now briefly comment on the importance of an integrated user experience for supply chain planners.

All About the Interface

When it comes to supply chain planning in general and synchronized planning in particular, user roles are converging. Now, almost all roles have access to planning and execution data and visibility across the entire design-to-operate lifecycle.

With technology and integrated environments that put information at our fingertips, it may no longer be required for organizations to maintain so many different roles for managing the minutiae of supply chain planning and execution. Today, you can bring all relevant information together in one unified user experience.

Think of it as the planner’s workspace – a unified access point to all data and analytics required to make decisions confidently and execute the decision from the same place. The data may span multiple time horizons, organizations, and vertical dimensions such as production, scheduling, procurement or transportation. This enables the convergence of traditional supply chain planner roles and emergence of a planner that handles an entire value stream.

Greater Responsiveness and Agility

Let’s say a company has an emergency customer order. This is an important customer, a lot of revenue is at stake, and you want to fill the order but not upset any current commitments to other customers. The challenge, quite frankly, is nothing new for you. You know that you need to scramble.

What exactly does the customer require – and in what quantity? What are the service levels expected? Do you have the materials in inventory? Maybe you do – but maybe it’s dedicated to other jobs. In such a case, you may consider rebalancing your inventory – taking materials slated for one job and reassigning it to this new job. But then how do you keep your other customers happy and deliver as promised? And what about the logistics? Do you have the freight carriers in place to move materials as needed and get the product out the door? What if additional change over is required on the production scheduling side?

In supply chain parlance, this is the definition of scrambling. But your customer with the emergency order needs an answer quickly. How can you get back with an answer within minutes rather than hours or days?

For such scenarios, the old methods of traversing systems, pulling data into spreadsheets, and sharing it all with colleagues via email doesn’t work. A planner’s workspace enables you to move faster. This is a game changer.

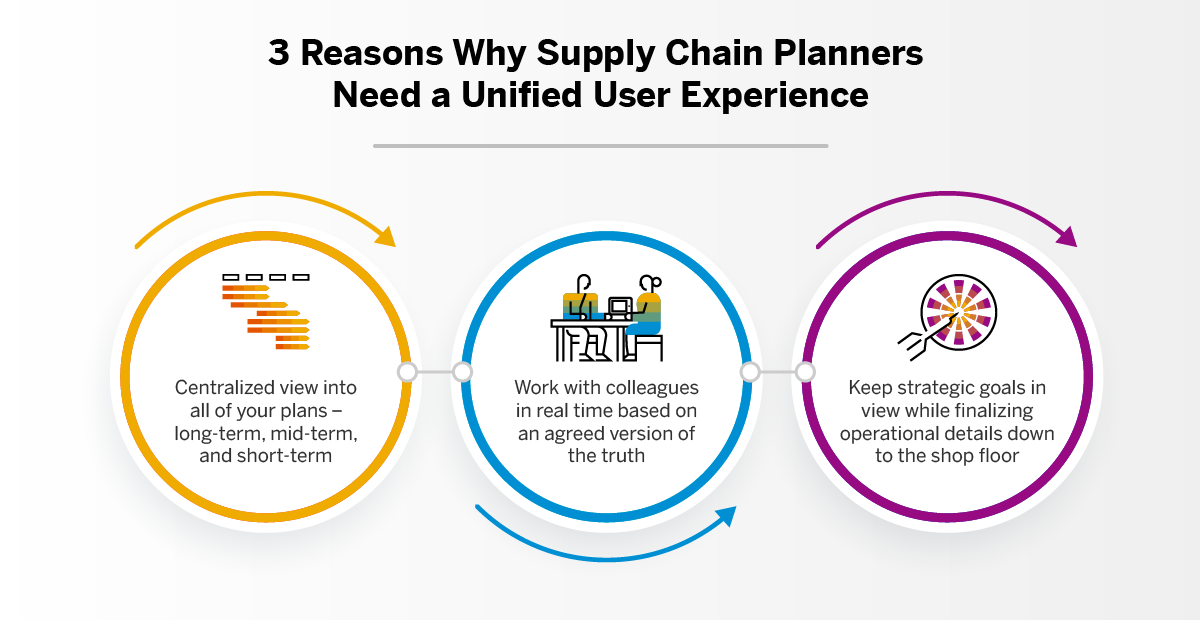

With a centralized view into all of your plans – long-term strategic plans, mid-term tactical plans, and short-term operational plans – you can make decisions in minutes because you can understand where you stand immediately. Hunting for data is dramatically reduced. And with collaboration tools built in, you can work with colleagues in real time based on an agreed version of the truth.

This, in the end, helps you follow through on the imperatives of synchronized planning. You can keep strategic goals in view even while finalizing operational details down to the shop floor. The interface matters tremendously. Without something like a planner’s workspace, you’re already putting yourself behind the eight ball in terms of agility and responsiveness to change.

In an age of disruption – whether it’s Covid or something else (and something else will always come up) – you need integration and visibility. You need the ability to access planning tools, see inventory levels, adjust schedules, move materials, nail down the logistics, run simulations, and evaluate the ramifications of your decisions. Bringing all such functions and capabilities together in a unified workspace for planning excellence is a key component for realizing success.