There is no doubt that the COVID-19 pandemic disrupted global value chains adversely. According to a Fortune magazine report, nearly 94% of the Fortune 1000 companies experienced supply chain disruptions. Whether it was restriction on movement of goods or consignments stuck at ports due to regional lockdowns or fluctuating consumer demand, the vulnerabilities accompanying global value chains were exposed.

The global health crisis also highlighted the weaknesses of traditional workflows in supply chain management and logistics: Manual, paper-based processes; siloed working and undefined roles; disparate and unstructured data; low or zero visibility of the end-to-end supply chain and logistics; lack of real-time monitoring, etc.

In the eye of the storm

The disruption also forced companies to relook their supply chain function end-to-end and figure out long-term measures to build resilience and agility. For instance, customers will continue to demand more in less time even after the pandemic is gone. But for companies to cope with this customer expectation, a drastic rethink of their supply chain management and logistics (SCML) is a must.

Here’s where technology plays a pivotal role, not only to provide intelligence and insights but also to enable new operational models. And Artificial Intelligence (AI), Internet of Things (IoT), Machine Learning (ML), Big Data analytics, and blockchain are some of the technologies that are rapidly redefining how SCML systems work.

How Supply Chain Heads are using AI and IoT

A well-managed supply chain is a crucial factor to gain advantage over the competition, especially in the present era where supply chains are intricate, spread worldwide, and decentralized. So, if AI earlier was only helping to address skills shortage and maintain inventories, the flexibility and adaptability of this technology is now allowing supply chain heads to be more innovative. From improving production planning to making more accurate forecasts, AI is allowing companies to minimize or eliminate errors completely.

AI, coupled with IoT, would allow supply chain heads to monitor and manage storage, transportation, supply chains, and warehouses efficiently and in real-time, without having to be physically present. These technologies also allow for planning and monitoring movement of goods so that unforeseen events (read pandemic, adverse weather conditions) can be managed well in advance.

Other immediate benefits of adopting digitalization and new technologies include:

- Smart scheduling and planning,

- Parameter optimization,

- Intelligent and proactive quality analysis,

- Proactive maintenance,

- Efficient analysis of maintenance and production costs along with precise estimation and control,

- Intelligent control of energy consumption and associated costs, and

- Real-time monitoring of production process and procedures.

What’s Next in SCML

As mentioned earlier, traditional SCML systems have now proven to be struggling with ever-changing customer demand, rapidly evolving operations planning, and the constantly changing state of business processes.

In 2022, these technologies aim to overcome all these challenges more effectively through a range of activities including providing sales, production and consumption forecasting, supplier selection, and demand management using Artificial Neural Networks. These technologies would help businesses become proactive with capabilities like agent-based systems, which perceive the surrounding environment and can act autonomously and proactively solve certain problems.

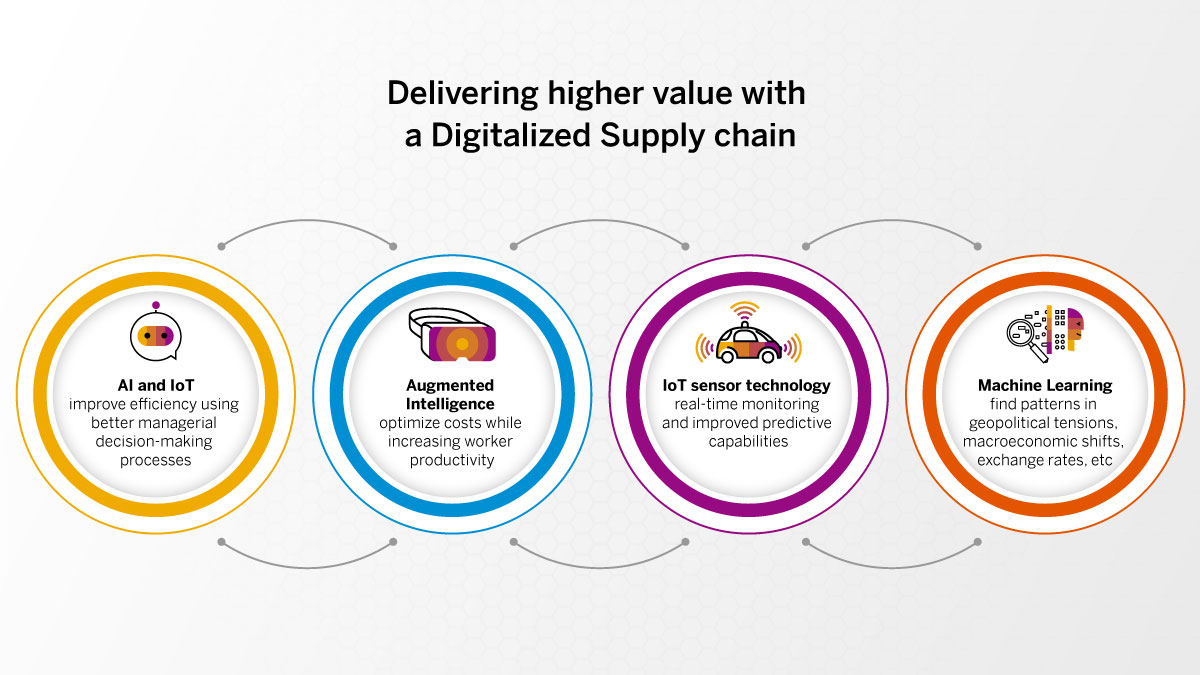

Next year, AI and IoT are also expected to help businesses through improved supply chain efficiency implemented by using better managerial decision-making processes, including multi-objective optimization of supply chain networks, partner selection in green supply chain problems, multi-product supply chain networks, and a problem-solving approach to closed-loop supply chains.

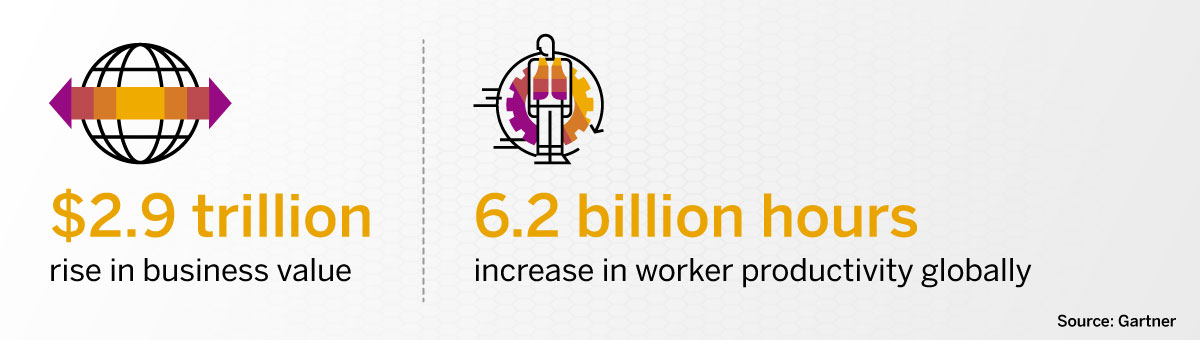

Augmented Intelligence along with AI is expected to spike in use as it would help reduce manual effort, helping companies optimize costs while increasing worker productivity. According to Gartner, it can create $2.9 trillion worth of business value and lead to an increase of 6.2 billion hours of worker productivity globally. By 2030, AI/Augmented intelligence is expected to surpass all other forms of AI initiatives. Essentially, this means professionals can do their work faster, reducing errors and saving costs.

IoT sensor technology will continue to play important roles and expand on its use cases. This technology helps track shipments. Connected IoT devices on consignments allow warehouses to track inventory, vehicles, and equipment through cloud services. Collaboration between IoT start-ups and container shipping companies are expected to increase next year given the inherent benefits, including real-time monitoring and predictive capabilities.

The need for real-time data will only increase. From gauging customer sentiments and trends to ensuring timely deliveries, data will play a critical role in deriving intelligent insights that drive strategic decisions. Machine learning-enabled risk assessment tools, for instance, can find patterns in geopolitical tensions, macroeconomic shifts, exchange rates, and other data.

According to Gartner, IoT is important because emerging supply chain techniques need the freshest, most accurate data. And being able to predict consumer shifts, more than demand, will become increasingly important post-pandemic.

The Experience Economy and Changing Paradigm

The consumer, today, no longer stops expecting once a good is purchased. The demand continues long after – the customer experience has become critical and sustaining a good customer experience has become central to this theme. But for businesses grappling with supply chain disruptions, how can sustaining good customer experience be a real possibility?

Digitalization of supply chain management and logistics allows this: where processes and systems that support mass personalization can be deployed; where collaboration with non-traditional ecosystem partners makes it possible to deliver higher value, and where efficient order fulfillment and delivery become par for the course.

Moving Ahead with SAP

The SAP digital supply chain management (DSCM) software allows enterprises to move from transactional SCLM to a digital, sustainable, strategy-led approach that will help them counteract unforeseen disruptions with agility and data-driven insights.

SAP offers global supply chain management software and tools, that allow for:

- Real-time insights into the supply chain,

- Identifying bottlenecks, and

- Mitigating risks as they arise with on-premises and cloud logistics management systems from SAP.

An integrated cloud-ready portfolio allows:

- Collaborative supply chain network

- Integrating business planning

- Optimizing inventory

- Procurement and supplier management

- Predictive analytics, AI, and Machine Learning

- Sustainably plan for ethically sourced material

And all these are achieved through predictive analytics, automation, and IoT capabilities, enabling resilient and sustainable supply chain management processes.

Specialized programs for various aspects of the supply chain management and logistics systems from SAP also give businesses a large number of options to choose from, depending on their needs. These programs include the following:

- SAP Transportation Resource Planning provides real-time visibility into transportation resources to allow businesses to fulfill their customer demands at minimal cost. The program integrates advanced analytics on historic data with forecasting capabilities to accurately forecast and monitor resource supply and demand.

- SAP Extended Warehouse Management is a program that allows a business to manage high-volume warehouse operations and integrate complex supply chain logistics with warehouse and distribution processes. Businesses can optimize inbound logistics management, storage and operations, and outbound logistics management.

- SAP Logistics Business Network is an open logistics network that connects business partners for intercompany collaboration and insights. It provides a central entry point to manage logistics transactions, exchange documents with key business partners, and gain transparency across the complete value chain through an open ‘network of networks’ strategy. It also allows for freight logistics collaboration, global track and trace options to monitor purchase, sales, and delivery fulfillment, as well as helping notify stakeholders of changes; and cross-company real-time alerts and notifications for product issues that also streamlines recalls.

- SAP Yard Logistics program helps businesses run more efficient and profitable supply chain logistics to maximize visibility into all yard processes and preview planned workloads with a range of visualization and reporting tools.

- SAP Transportation Management program helps reduce transportation complexity by integrating fleet and logistics management throughout the business’ network. The program also provides real-time visibility into global transportation and domestic shipping across all transportation modes and industries.

As companies now demand greater agility in their supply chain processes and practices, they are beginning to realize that digital transformation is a necessity. There’s no getting away from the fact that global value chains are here to stay for good, but supply chain heads will need to juggle the demand for agility and efficiency with sustainability mandates while making a steady recovery from COVID-induced afflictions.

Supply chain sustainability means being able to manage environmental, social, and economic impacts with good governance practices. And here’s where SAP DSCM can help. By adopting an end-to-end sustainability mission as part of its solution strategy (from design to decommissioning) the SAP portfolio ensures that the key principles of sustainability are embedded in it. This ultimately addresses the three areas customers focus on –people, planet, and profit.