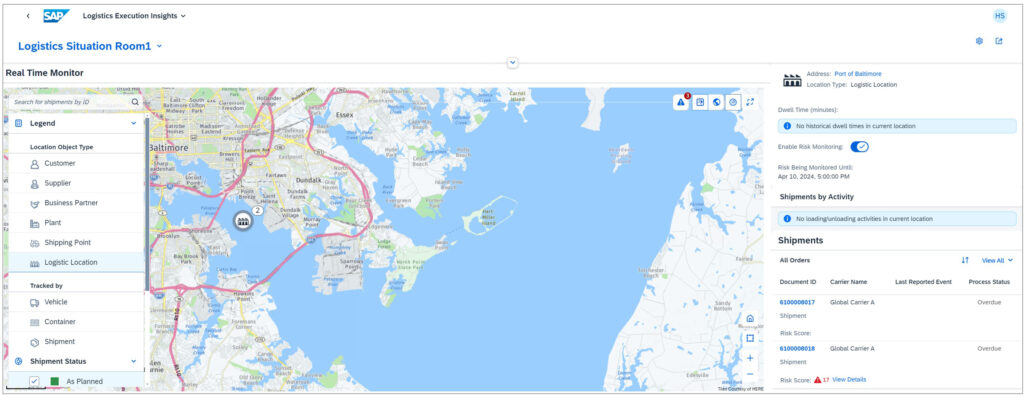

A small, round incident indicator hovers over the map of outer Baltimore Harbor in the virtual logistics situation room. That indicator corresponds with an alert reading “Risk Score: ! 17,” which warns of a high-risk event disrupting transportation.

On another day, this would be one of many alerts that supply chain logistics professionals see from SAP Business Network’s logistics collaboration solutions. Unfortunately, on this day there is more to the story than the indicator on the map can tell us.

By now, we’ve all seen photos and videos of the cargo ship Dali striking the Francis Scott Key Bridge, causing a section to collapse into the Patapsco River in Baltimore’s outer harbor on Tuesday, March 26. They tell the story on a human level.

This event was a terrible tragedy where people lost loved ones. We are also mindful of the thousands of people whose livelihoods have been affected and of the impact this tragedy will have on the City of Baltimore and surrounding areas for years to come. It is a reminder that transportation logistics is not just a routine process of moving goods from point A to point B. It’s high stakes, dangerous work that we depend on to keep the world’s economic engine running.

Recovering from the Disruption: Three Scenarios

Another reality to the tragedy is that even as events were unfolding in Baltimore, supply chain and logistics professionals were compelled to act quickly to address a shockwave of related disruptions. As one of my colleagues noted, “Globally, companies immediately devoted extra resources to determine what inventory they have at the Port of Baltimore, what’s on the water headed there, and what’s leaving their factories that can be rerouted.” Buying organizations looked closely at inbound shipments, while their suppliers were checking how the disruption would impact outbound deliveries.

Increasingly today, buyers and suppliers rely on technology to gain visibility into the global supply chain. This makes it possible to track shipments, reroute them as needed, or take other remedial action. To explain this further, I’d like to address three port disruption scenarios and how suppliers and buyers can use SAP solutions, including SAP Business Network Global Track and Trace, SAP Business Network Freight Collaboration, and SAP Transportation Management, to recover and be more resilient through adversity.

1. Identifying and Tracking Outbound Shipments Impacted by a Port Closure

When a port is closed, especially unexpectedly, suppliers immediately turn their attention to outbound shipments and their committed delivery dates. Through logistics collaboration on SAP Business Network, suppliers and shippers can receive alerts about high-risk events affecting their shipments. They can also get alerts about deviations from planned or expected estimated deliveries. SAP solutions can generate these alerts based on global risk data from services like Everstream and from global positioning and event data from carriers and logistics visibility service providers.

However, knowing about delays is only one part of a business plan for supply chain resilience. To respond effectively, shippers also need to know the business impact. Which deliveries are impacted? Which customers? SAP Business Network Global Track and Trace helps keep global logistics visibility in the context of the business. This can enable shippers to identify and contact affected customers and prepare a recovery plan.

Similarly, buyers using SAP solutions can track inbound shipments. They can see how changes to the delivery date of a purchase order or stock transfer order will impact their inventory levels and production plans. This helps them avoid stock-outs and production delays that can ripple through the supply chain to their customers.

2. Adjusting for Shipments That Are Routed Away from a Closed Port

When a port is closed by a disruption, shipments headed there must be rerouted to another port. In many instances, new arrangements must be made for ground transportation from that port.

With SAP Business Network Global Track and Trace, shippers can see that the ocean vessel carrying their shipment has been rerouted. Then, they can use SAP Business Network Freight Collaboration to cancel ground transport out of the closed port and tender an order from the new port to the desired destination.

3. What About Shipments Stuck at a Port Suddenly Closed by Disruption?

If a port is suddenly closed, containers will remain piled up at the port, waiting either for pickup by another ocean vessel or for urgent ground transport to another hub. When a port is closed for an extended period, shippers must make alternative plans.

To do this efficiently and effectively, shippers can use SAP Transportation Management. The application helps them develop new plans to move their goods through new routes or with new carriers. This can include everything from load planning and balancing to leveraging new lanes and delivery methods.

Then, with a new plan in place, shippers can use SAP Business Network Freight Collaboration to collaborate digitally with carriers to execute the plan.

Anticipating and Avoiding Future Disruptions

Using technology to react to a supply chain disruption is not new. Inventory and production planning solutions have long helped businesses adjust when supply is affected. However, it may be even more important to understand how technology enables organizations to anticipate and even avoid disruption before it impacts their supply chain. This is the essence of logistics visibility.

Recovery and Resilience

Unexpected tragedies like the one in Baltimore Harbor are never easy on the many people impacted personally and professionally. As its effects ripple out across the world, we are reminded of the power of resilience. Building resilience is an axiom of supply chain management. Unfortunately, the collapse of the Francis Scott Key Bridge is yet another resilience test for the world’s supply chains.

In the end, I believe the people of Baltimore and surrounding communities will show us what resilience really means. I also know that as recovery is achieved, supply chain practitioners around the world will do what it takes to make safety a top priority as they deliver what is needed to keep world economies running.

Doug DeLuca is an SAP Business Network product marketing manager.