The pandemic has done a good job of accelerating trends like digitization, remote working, and virtualization, but many companies were caught unawares.

According to a survey commissioned by London-based Studio Graphene, almost half of UK businesses (49%), were not prepared to transition to remote working when the pandemic hit, and 39% were not even using technology that supported remote working when the lockdown was announced. Gearing up was an issue: 48% of firms have had to invest in new computer programs since the outbreak, 72% in new hardware.

At the same time, logistics leaders were blindsided by COVID-19, even though they are used to dealing with interruptions such as shipment delays or demand spikes. Disruptions caused by the pandemic have exposed many gaps in logistics operations; supply chain leaders are now scrambling to overhaul processes to manage upheavals.

But for intelligent companies, it was mostly business as usual, thanks to digitalization, which according to Gartner, is the use of digital technologies to change a business model and provide new revenue and value-producing opportunities.

Serving Customers

For example, COVID-19 has changed the way we shop for food. It is no surprise that grocery stores have done particularly well during the pandemic — everyone needs to eat and stock up on dry goods. What is surprising is the change in buying habits: people are spending less time in stores, there is less human contact, and stores have become more transactional. People are also more conscious about sustainability in the food chain.

Daniel Lundh, co-founder of LIFVS, Sweden’s first fully digital unmanned grocery chain, has a tech tale to tell.

The company started as a chain of self-service stores in rural areas stocking about 500 items typically found in a grocery store. The business is based on innovative technology solutions like machine learning to drive replenishment. Store entry, goods scanning, and payment are all done using an app. Through the app, LIFVS has access to all customer data, enabling personalization and tailor-made communication. Only by tracking everything with data analytics can the company customize highly personalized journeys for every individual.

The entrepreneur, who sees his company as more of a tech startup than a grocery retailer, says LIFVS already had the right business model in place at the start of the pandemic. Then it was just a matter of opening a new store every second week to meet mounting demand. The trend is continuing.

Meeting Demand

How do companies ensure the right products make it to the shelves in the first place?

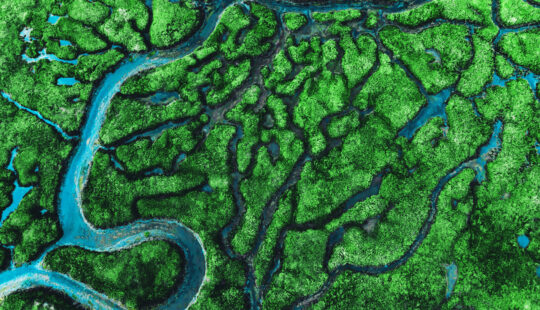

Companies like Royal Greenland solve this challenge with an app. Fisherman on the North Sea are now able to cast their nets based upon what is currently in demand in far off markets like Japan. According to a report published by The Nature Conservancy, supply chains involving seafood are uniquely complex, especially those that are based on wild-caught fish, which face higher uncertainty and risk than farm-raised chains due to ever-changing environmental and biological conditions.

That makes it hard to match supply to demand. To help optimize the process and improve regulatory compliance, Royal Greenland implemented SAP Integrated Business Planning for Supply Chain. This cloud-based solution has helped advance the company’s forecasting and planning capabilities and improve data transparency by establishing a common, integrated platform for sales and operations.

The company is also digitalizing the process of bringing the fish into factories and implementing registration and quality control procedures with apps.

Delivering the Goods

Trucking is also benefiting from digitalization. When lockdowns forced office closures, digital trucking company Girteka Logistics was able to set up home offices for 3,000 support staff within weeks. This enabled the company to focus on what really mattered: delivering food and medical supplies across Europe as COVID-19 surged.

For Girteka, digital technology is the foundation for everything, from teaching people new skills to meeting customer expectations and becoming more sustainable. Having fully integrated and automated systems and processes has relieved the workforce of repetitive tasks and enabled them to take tighter control of operations. Instead of scaling back transformation efforts during the pandemic, Girteka went ahead with plans to digitize the entire business and grow.

Martynas Sarapinas, CIO and Executive Board member at Girteka Logistics, stated in an interview that becoming an intelligent enterprise requires an end-to-end digital solution. While the crisis is forcing businesses to reevaluate supply chains and business models, Sarapinas is secure in the knowledge that his company has the digital foundation to meet any customer expectations in the future.

Freight transport is yet another key link in the supply chain. To avoid potential delays, smart companies such as Canadian Pacific have modernized their systems reducing downtime from an average of 12,000 hours per year to less than 60. If trains do stop in their tracks, a satellite-based solution from Ovinto provides instantaneous alerts so corrective measures can be taken immediately.

These are just a few examples of how digitalization is enabling companies to react quickly to disruptions without breaking stride. No one knows what tomorrow will bring, but the evidence suggests that companies with digital processes are most likely to adapt and thrive.