This year at SAP Sapphire, SAP unveiled its vision for AI: to transform supply chains from digital to adaptive and ultimately toward autonomous, characterized by improved massive data-driven intelligence, system-driven recommendations, predictive insights, and contextualized decisions.

According to the IDC 2024 Supply Chain Survey, 63% of respondents “have an AI strategy linked to business objectives” to improve operational efficiency, business resilience, and increase employee productivity.

Our objective in this digital, adaptive, autonomous supply chain journey is to utilize the breadth of AI technologies to assist customers in achieving their business goals and drive significant value regardless of their current maturity level in business practices and technology.

Business Challenges in Integrating AI

Business leaders see significant challenges in integrating AI into business applications and processes, especially when trying to make sense of vast amounts of unstructured data. These challenges specifically stem from:

- Data quality: Data is inconsistent or not reliable nor current.

- Organizational Readiness: Organizations continue to rely on on-premise systems that pose challenges around stale data, integration, and scalability.

- Volatility: Global AI regulations are constantly evolving, for example the EU AI Act. Technologies such as large language models (LLMs) are also rapidly changing in performance and price with new models and providers popping up almost weekly.

These challenges underscore the need for a thoughtful approach to integrating AI into supply chain processes. SAP Business AI delivers a comprehensive set of relevant, reliable, and responsible AI solutions that effectively tackle many of these hurdles and ensure seamless AI adoption throughout your supply chain processes.

- For additional insights into relevant, reliable, and responsible AI, see “Trustworthy AI Can Reinvent Companies and Help Resolve Global Challenges” from SAP CEO Christian Klein.

Our Vision of AI-Enabled Supply Chains

For decades, SAP has led the way in supply chains, empowering its customers to streamline their complex end-to-end supply chain processes for enhanced efficiency, agility, and resilience. The SAP Supply Chain portfolio introduces innovation through various technologies, including AI, to transition your supply chain from digital to adaptive, with the ultimate vision of instituting an autonomous supply chain.

There are three possible maturity levels where you could stand in your business transformation. It is also important to acknowledge that different lines of business are on different maturity levels in an organization – while supply chain planning may already be somewhat adaptive, manufacturing operations may still be at the start of a digital transformation.

- Digital: Digitalization is the starting point. The SAP Supply Chain portfolio automates manual processes, enabling a seamless, digital end-to-end business process and digitalizing paper-based systems. This results in better access to data, greater visibility, and control over the entire supply chain, setting the foundation. Most importantly, SAP provides the tools and systems to get data ready for more advanced stages.

- Adaptive: This step is marked by an integration of cutting-edge technologies into business processes, including the use of predictive analytics and simulation for decision-making and Big Data, as well as the introduction of Joule, SAP’s copilot for every supply chain cloud application. These technologies empower supply chain professionals with intelligent insights and recommendations, enhancing decision-making for greater agility and resilience.

- Autonomous: Next, we envision a path characterized by technological, procedural, and data enhancements that will propel the supply chain into an autonomous era. This transition will happen gradually but ultimately enable supply chains to operate autonomously with minimal human intervention, resulting in even greater efficiency, adaptability, and responsiveness. It empowers supply chain experts to focus on truly value generating activities and spending precious time on only the most critical disruptions and business opportunities.

Technologies that Lead Toward Autonomous Supply Chains

SAP has been developing innovative AI capabilities that are fully integrated across digital supply chain applications, catering to diverse customer technology readiness levels. For example:

- Optimization models, rule-based predictive analytics, and heuristics improve, for instance, transportation plans, production scheduling, supply plans and spare part fulfillment. This allows a powerful way to automate decision-making in balancing conflicts of interests, such as customer service levels versus supply chain cost.

- SAP-owned machine learning is applied across the SAP Supply Chain portfolio; for example, in gradient boosting algorithms for demand forecasting, intelligent lead time predictions and failure curve analysis. SAP also offers customers a “bring-your-own-model” approach to enable extensibility for specific domains such as visual inspection and anomaly detection.

- Generative AI, when embedded in digital supply chain applications and combined with Joule, will allow users to conduct complex business transactions in simple conversational ways. We will augment tasks like conducting what-if scenarios for supply chain planning, assisting in new product ideation, analyzing manufacturing issues to accelerate the onboarding of new equipment, and assessing advanced failure modes of assets with generative AI.

With these technologies, our goal is to support customers wherever they stand in their journey and help them move from a focus on mere digital transformation to highly adaptive processes — and ultimately toward autonomous supply chain systems.

Examples of AI Innovations

Let’s explore specific innovations delivered in the SAP Supply Chain portfolio: These cases are classified according to their primary focus on digital, adaptive, and autonomous as a continuous journey. These innovations will be enriched over time and every business may find themselves at a different stage of maturity in different parts of their supply chain processes.

Digital

Intelligent Lead-Time Prediction for More Accurate Integrated Business Planning

This machine learning extension enables the extraction of historical lead times from goods movement data in SAP S/4HANA and analyses outliers and key influential factors for lead time changes to predict future lead times. The results are then uploaded as input for planning runs within SAP Integrated Business Planning, thus facilitating better decisions, and enhances plan adherence by considering the dynamic nature of actual lead times and future trends.

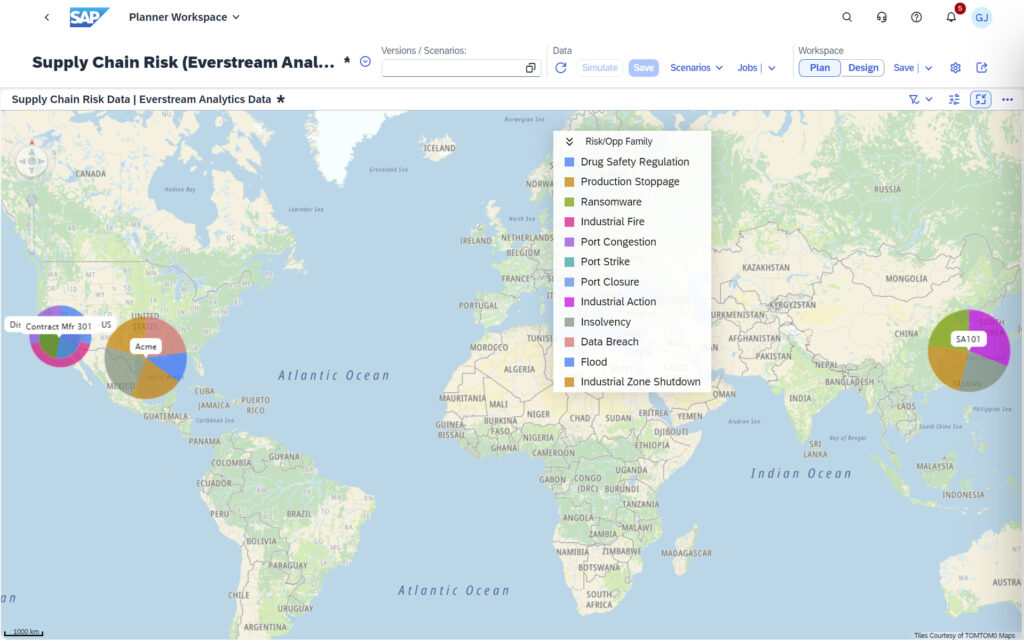

Everstream Powered Risk-Aware Supply Chains for SAP Integrated Business Planning

Critical data for decision-making can sit outside of the four walls of a company. Using external network data is imperative for better decisions based on supply chain risks in a digital transformation. This capability integrates external incident data — for example from Everstream Analytics — into SAP Integrated Business Planning and enables companies to proactively anticipate and manage external risks in their supply chain planning process. This integration allows supply chain planners to perform risk-aware planning by actively reflecting external risks affecting their supply chain, such as geopolitical shifts, material shortages, global regulations, extreme weather events, and more. Figure 1 illustrates this innovation:

Adaptive

Product Design and Formulation

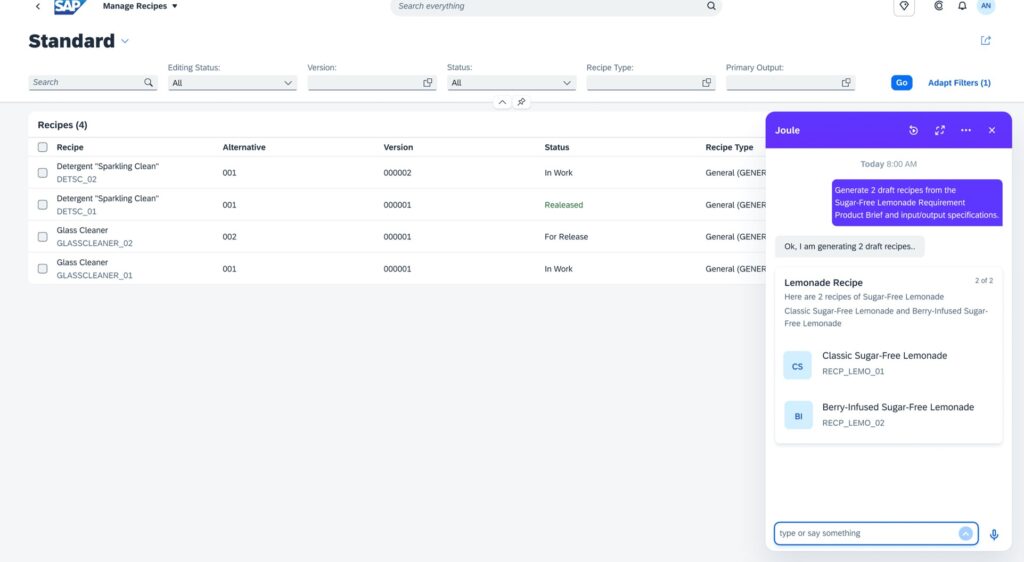

SAP Product Lifecycle Management (SAP PLM): Generative AI for Recipe Formulation

In the process industry, technology plays a crucial role in recipe creation and formulation to meet consumer demands. A fast time-to-market of launching a new recipe, in compliance with local regulation and sustainability targets, can be paramount to the competitiveness of a company. Generative AI integrated into SAP PLM assists in developing, enhancing, and customizing recipes, thus expediting product innovations, enhancing productivity, and supporting product compliance and sustainability for manufacturers of formulated products. Figure 2 illustrates this innovation:

Logistics

SAP S/4HANA Transportation Management: Intelligent Goods Receipt Analysis

In high-volume logistics industries, the manual tasks involved in inbound goods receipt can be time-consuming and error-prone. By leveraging AI-based document extraction, this use case automates data extraction from freight documents, seamlessly integrating them into SAP S/4HANA, enhancing efficiency, accuracy, and time savings.

Asset Operations

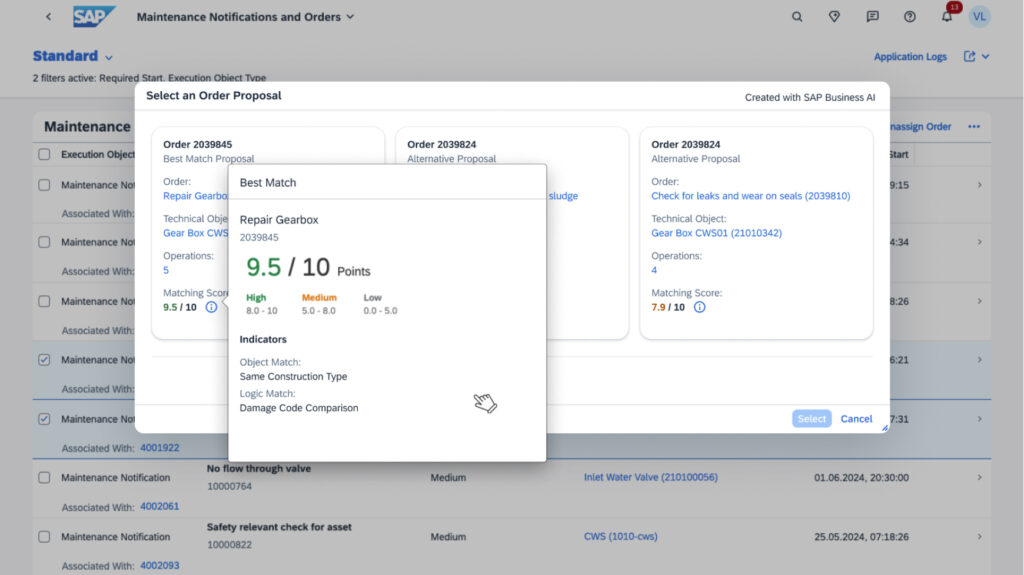

SAP S/4HANA Enterprise Asset Management: Intelligent Maintenance Order Recommendation

LLMs optimize maintenance planning, promote agility, and improve asset performance and reliability in SAP S/4HANA enterprise asset management. In this innovation, generative AI supports users in the assessment of maintenance requests by recommending appropriate tasks and spare parts, thus enhancing operational efficiency. Figure 3 illustrates this innovation:

Autonomous

Supply Chain Planning

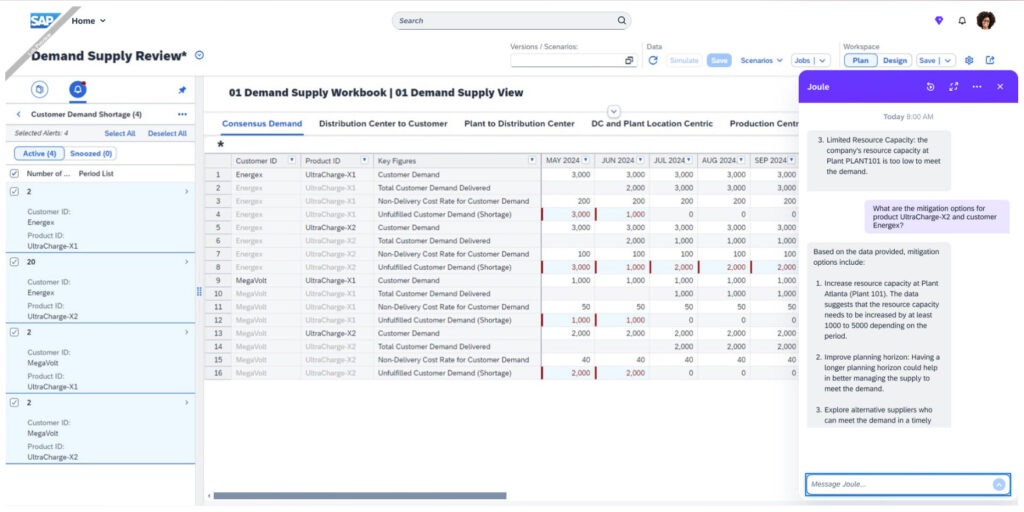

SAP Integrated Business Planning: Interactive Planning Assistant

Demand, supply, and inventory planners often use complex machine learning algorithms. By using generative AI and conversing with Joule in natural language, planners can gain insights into the models’ variables, constraints, and decision processes, leading to much more informed decisions and proactive planning. SAP helps customers boost explainability but also enable what-if scenario simulations for complex planning decisions. Figure 4 illustrates this innovation:

- Learn more via this interactive value journey.

- To try out a use case, register in the Early Adopter Care Program.

Manufacturing / Industry 4.0

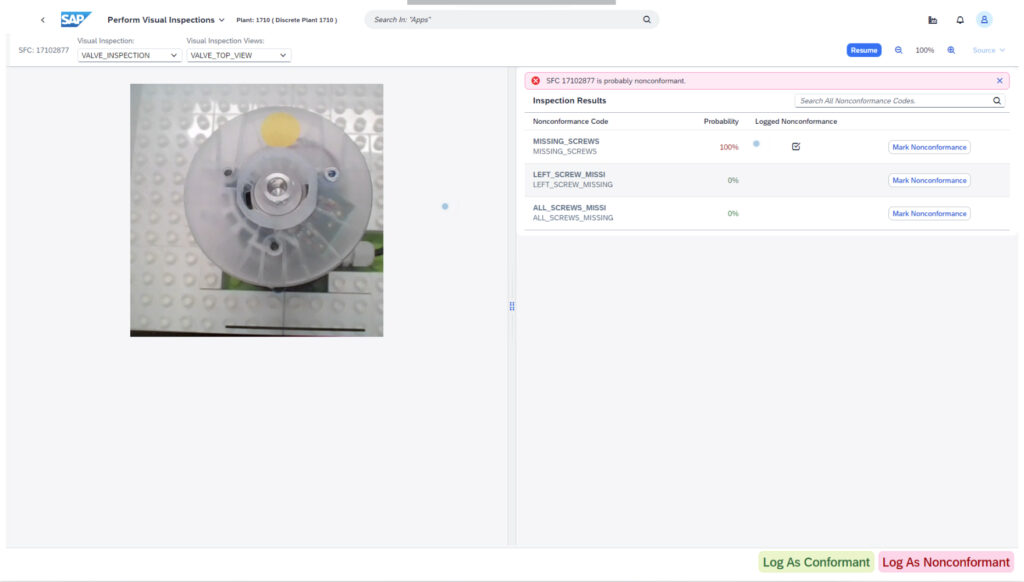

SAP Digital Manufacturing: AI-Driven Visual Inspection

In industrial manufacturing, human-led visual inspection can lead to potential quality issues and is synonymous with a higher degree of manual labor. This capability applies computer vision AI into the production process to automatically identify defects and allocate non-conformance for production decisions, thus supporting a consistent and objective quality analysis that contributes to cost savings associated with reworks and recalls. Figure 5 illustrates this innovation:

Join the evolution and embrace AI, whether you are in a digital transformation or already driving toward adaptability or are taking your first steps toward autonomous supply chains or functions.

More Details

Ready to revolutionize your supply chain using artificial intelligence? Here’s how to get started:

- Register in the Early Adopter Care Program to explore Joule in SAP Integrated Business Planning for conversational search

- Dive into the IDC report “The Importance of AI in Supply Chain and Operations” for insights into AI’s pivotal role and its use cases in supply chain and operations

And stay tuned for more Early Adopter Care programs and updates on future innovations.

Dominik Metzger is head of SAP Digital Supply Chain for SAP Product Engineering.