Creating a sustainable distribution business that stands the test of time and market disruption requires a different mindset, different practices, and different systems. You cannot solve today’s challenges with yesterday’s tools.

To discuss the topic of technology adoption in wholesale distribution, I sat down with Scott Knote, chief information technology officer at Powell Electronics, to discuss the journey to become an intelligent enterprise.

During the session, Knote shared, “SAP S/4HANA helped us stop driving in reverse; we can now look forward, plan, and execute on the plan.”

To learn more about the latest market disruptions driving wholesale distribution and the key drivers behind Powell Electronics’ decision to adopt SAP S/4HANA, watch the on-demand webinar here.

New Market Disruptions Drive New Business Models for Distributors

Even before COVID-19 took hold, the wholesale distribution industry has continuously been a vital part of the economy. The last year has further elevated the stature of wholesale distributors, as they played a vital role in the distribution of essential goods throughout the pandemic.

Considering its place in the supply chain, wholesale distributors have always been faced with a high amount of competitors. This has prompted forward-thinking distributors to rethink the way they deliver value to their customers through value-added services and logistics and information service products. These offerings allow companies to avoid disintermediation by offering something that manufacturers or traditional competitors cannot, aiding customer loyalty.

Another way distributors can add value is through offering tighter collaboration with customers through project-based services. As the business world becomes more complex, customers are looking to consolidate their supplier base with a smaller set of strategic partners that they can trust to meet their various needs.

These trends and market disruptions are accelerating the industry transformation and thereby forcing distributors to rethink the business systems, platforms, and applications that can help them stay agile and change with the times.

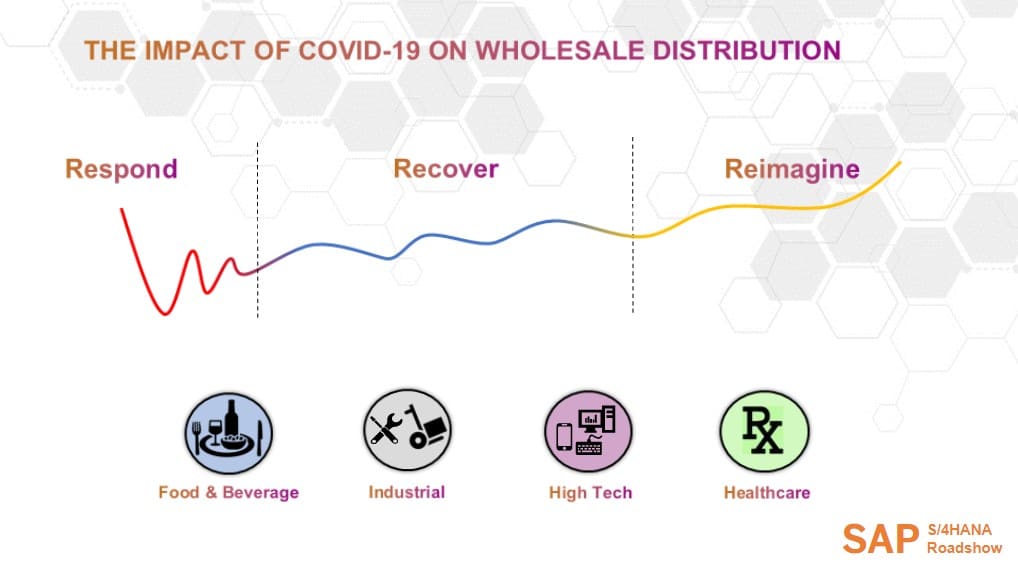

Further accelerating these industry trends, COVID-19 has had a unique impact on each of the sub-segments:

Further accelerating these industry trends, COVID-19 has had a unique impact on each of the sub-segments:

- Food & Beverage: This subsegment was the most impacted, as restaurants and other food service companies have been limited seating capacity amid social distancing measures

- Industrial: As many industrial investment projects were delayed and manufacturers decreased production due to softening demand, this subsegment experienced a downturn.

- High Tech: This subsegment was well positioned to ride out the pandemic, as the influx of employees working from home and the need for infrastructure to support this shift increased

- Healthcare: The global supply chain of pharmaceuticals was greatly impacted by manufacturing hubs such as China and India, but this subsegment proved crucial to distribute personal protective equipment (PPE) and coronavirus treatment-related medication

To take a proactive approach to addressing industry trends, leading distributors like Powell Electronics are expanding beyond traditional industry boundaries to become proactive, insight-driven companies.

How Powell Electronics Transformed with a Cloud-First Approach

Since 1946, Powell Electronics Inc. has followed an unbroken record of growth to become one of the world’s largest authorized distributors of electronic components and value-added services. Contributing to that growth is the company’s ability to anticipate its customers’ technology, service, and product needs.

Most recently, Powell sought to provide a better e-commerce experience for customers and suppliers. Due to a massive amount of system customizations, Powell knew its existing enterprise resource planning (ERP) system was not up to the task.

Knote shared that Powell Electronics “realized that the paradigm is shifting; that both the customer and buyer sides of our business are becoming increasingly complex. We wanted to minimize the training requirements while increasing the speed to market for onboarding new manufacturers and technologies. We wanted to position ourselves to pivot should something an external market demand cause changes to our overall business.”

So, the company sought a digital transformation that could support its assemble-to-order operations, which use configurable product permutations for more than 250,000 unique end items within a catalog of 8 million SKUs. Powell hoped happier customers and a better technology infrastructure would prepare the company for worldwide expansion.

“SAP S/4HANA helped Powell tune key business success levers and increase its speed of relevance for an increasingly complex market,” Knote said.

Watch the on-demand webinar to learn more about Powell Electronics’ journey to becoming an intelligent enterprise.

John McDonnell is industry advisor for Wholesale Distribution at SAP