When Shinhwa Auto USA Corp. fully realized the massive scope of its North American growth ambitions, one thing became clear to its leadership team: there needed to be capital investment to match.

The South Korean-based global automotive parts manufacturer began by building a US$42 million factory at Auburn Technology Park West in Auburn, Alabama, to boost output of aluminum parts for its auto customers. That U.S.-based hub underwent a $70 million expansion project two years later, adding high-pressure aluminum die casting and post-processing equipment to its assembly lines. Now, two more years later, Shinhwa is putting the finishing touches on a brand-new $192 million manufacturing facility in Auburn, designed to further increase the company’s capabilities as it works to meet current and future demands stemming from electric vehicle production.

Amidst all of this ambition and expansion, however, there was one element of Shinhwa’s business that didn’t measure up: its IT systems. In other words, while the company was building out all the front-facing manufacturing tools it could ever need to serve customers, its success hinged on strengthening its back-office processes so the business could truly be run efficiently and effectively.

That’s why Shinhwa chose to work with SAP.

Start Your SAP Engines

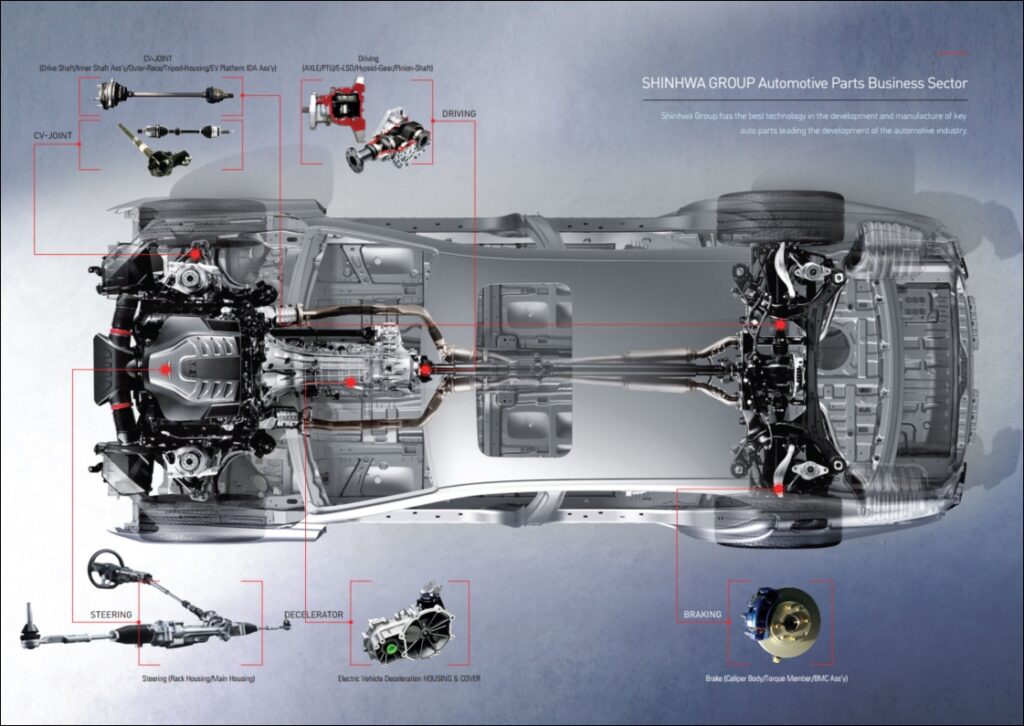

Shinhwa specializes in automated production lines, automobile parts, and aluminum casting, serving industry leaders like Tesla, Hyundai, and Kia from its U.S. headquarters. The Auburn factory expansion is specifically intended to meet the needs of additional electric and combustion engine vehicle manufacturing opportunities like this, increasing the capacity of die casting and machining operations, for instance, and further enabling diversification and growth in Shinhwa’s customer base.

The capabilities of Shinhwa’s original back-office systems were lacking. Its IT infrastructure was heavily customized and didn’t integrate between enterprise resourcing planning (ERP), manufacturing execution systems (MES), and accounting software, making it nearly impossible to accurately forecast or plan regular financial checkpoints and processes. This led to an abundance of human error, which made Shinhwa’s IT systems not only incompatible with its goals for expansion but with growth and success generally.

With 96% of Fortune 2000 automotive companies running on SAP, the choice for the next step of Shinhwa’s technological evolution was an easy one. Its leadership team decided to embrace GROW with SAP, an offering designed for scalable, plug-and-play implementations in the public cloud. With it, the company can operate in a more streamlined manner on a global, standardized scale.

Shinhwa’s technological goals include the replacement and automation of all manufacturing processes; data collection from shop floor-, finance-, and supply chain-related systems; improved data integration with partner and customer systems; and modular steps forward in its IT architecture. This will enable the company’s systems to grow with it and ensure it becomes the supplier of choice for the world’s leading vehicle manufacturers.

“We want to set the standard for the automotive industry going forward when it comes to IT systems and back-office processes,” said Steven Lee, IT senior manager at Shinhwa.

Ultimately, Shinhwa expects to grow from its current manufacturing plant plus two additional plants, which will be completed by the end of the year, to seven, which will help serve the rising demand the company is expecting to see from U.S.-based auto customers over the next decade.

“SAP S/4HANA and SAP Digital Manufacturing really showed us what’s possible,” Lee said. “We expect this project will help us deepen our American roots and position us for whatever global change is yet to come.”

Shinhwa is following an ambitious migration and implementation schedule, made possible by the agility and flexibility of a public cloud project. The company’s go-live is expected to be January 1, 2024.

“We’ve already invested nearly $200 million into the Auburn area, and we’ve created nearly 200 jobs,” said Lee. “With this SAP relationship, we are announcing our commitment to much, much more than that. We’re here to stay and keep creating new global standard.”

Lori Rosano is SVP of Public Cloud at SAP.