The manufacturing industries were early movers in digitizing business processes. Material requirements planning (MRP) was defined and digitized in the 1950s, long before the term enterprise resource planning (ERP) was coined. Over time, production and supply chain equipment were integrated with business processes for real-time insight and control. But it would take a long time until digital technology was built into the actual machinery and day-to-day operations.

Add real-time connectivity over the Internet of Things (IoT) and we reach the current stage of Industry 4.0, which enables completely new business processes and business models that go beyond the classical paradigm of designing, making, and delivering products and include the operations through decommissioning, closing the cycle in the spirit of a circular economy.

Industry 4.0 is a set of technologies used with a new mindset to drive the automation of manufacturing and operations processes with smart technology. It starts with analyzing where and how business value is generated and then designing, making, delivering, and operating solutions that drive the right business outcomes.

Every industry success story starts with a new way of thinking. Maybe a customer doesn’t need a machine, but something the machine does or produces, such as powering an aircraft, making car parts from sheet metal, pumping concrete, compressing air.

That’s why digitalization is first about a mindset, and then about technology. Digital leaders think about how they do things today and reimagine doing them better using digital technologies. They don’t only challenge how they do things; they challenge what they are doing.

A true digital leader, for example, doesn’t just train service technicians to improve service quality and reduce costs. They might redesign their products and connect them with intelligent technology, enabling the machine to call the service with a list of its symptoms, so that the technician arrives with all the right spare parts on the first visit.

An Intelligent Strategy

We have always managed business processes in real time with their material flows and their value flows — that’s standard textbook stuff today. What is new now is the way we model supply chains, products, and the manufacturing processes with digital twins through a holistic process we call design to operate.

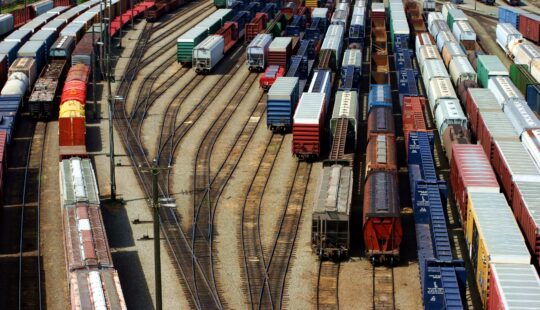

The strategy for Industry 4.0 at SAP goes well beyond smart manufacturing in factories and plants. It connects production with end-to-end process execution across the supply chain so companies can reach a new level of connectivity and adapt to change on the fly.

It starts with intelligent products that are designed to deliver outcomes. For example, in Brazil, tractor manufacturer Stara is equipping its agricultural machinery to collect real-time data about what happens in the fields. The data is used to optimize irrigation and minimize the use of fertilizers, resulting in higher yields and more sustainable farming practices.

Next, it requires intelligent factories and logistics that are digitally integrated from the top floor to the shop floor, enabling faster, better decision-making on the business end whenever there are disruptions or new opportunities. For example, Porsche and press manufacturer Schuler have set up a smart press shop that allows the company to make automotive body parts in small numbers using a highly automated, flexible process.

The third element in the design-to-operate process is intelligent assets such as digitalized machines that collect and combine data through sensors and from SAP solutions. Endress + Hauser is a global leader in measurement instrumentation, using Industry 4.0 technology to extract and process sensor data used for predictive analytics to reduce the unplanned downtime of machines.

And finally, the design-to-operate process relies on intelligent people who understand complex scenarios and are empowered to make smart decisions with the right tools. Automotive supplier Schaeffler has equipped its digital assistants with SAP technology that supports its employees with context-sensitive information, intuitive user interfaces, and natural language processing.

Intelligent Decisions

We all know intelligence sits in the brain, but the brain is useless without a nervous system, sensors, and muscles to interact with the world around it. SAP solutions can be the intelligent tools that enable the brain of the enterprise to collect and interpret all the data they can get from their ERP systems, their shop floor systems, and their ecosystem of customers, suppliers, and service providers. This enables them to make smarter decisions — in real time.

Enterprises that are truly intelligent use Industry 4.0 technologies such as machine learning and artificial intelligence (AI) to learn from good and bad decisions. That’s how they can make better, more intelligent decisions in a manufacturing environment that is constantly changing due to varying customer demand. These are the next practices that will help manufacturing companies increase productivity while producing high quality, individualized products in a sustainable, efficient manner.

Learn more about how SAP is helping manufacturers

reimagine a digital future.

Peter Maier is president of SAP Industries and Customer Advisory.